Launch the open cycle TESTapp located at the page TEST. TESTapps. Systems. Open. Steady. Specific. PowerCycles. PC Model.

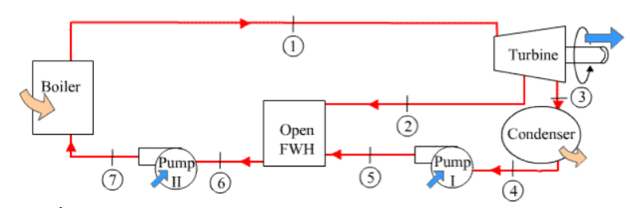

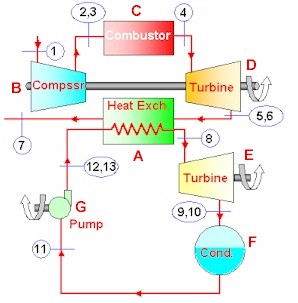

Let us set up the cycle as follows: Device-A (turbines): Instead of treating the two turbines separately, let us analyze them as a composite device with two exits, State-3 and State 5, and one inlet, State-1. Note that State-2 and 4 are isentropic states, which are necessary to evaluate the actual exit states. Device-B (condenser): Constant pressure heat rejection from State-5 to State-6. Device-C (pump-I): Compression from State-6 to State-8 (with State-7 being the isentropic state). Device-D (FWH): Constant pressure mixing between State-3 and State-8, producing State-9. Device-E (pump-II): Compression from State-9 to State-11; (with State-10 being the isentropic state). Device-F (boiler): constant pressure heat addition from State-11 to State-1.

Let us assume a mass flow rate of 1 kg/s through the boiler and leave mdot3 (the rate of bleeding) unknown, expressing all other mass flow rates in terms of mdot1 and mdot3. Evaluate the states as follows.

State-1: Enter p1, T1, and mdot1 (assume 1 kg/s), and Calculate.

State-2: Enter p2, s2 ('=s1'), mdot2 ('=mdot1'), and Calculate.

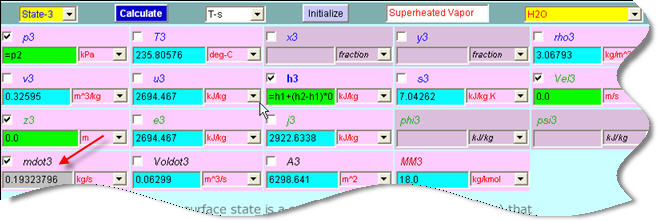

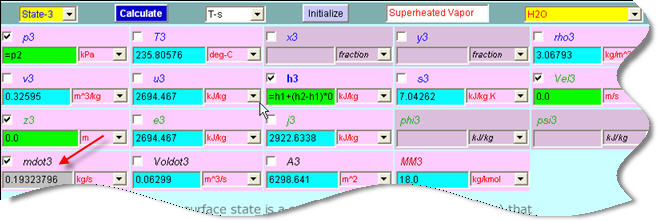

State-3: Enter p3 ('=p2'), h3 ('=h1+(h2-h1)*0.88'), and Calculate (mdot3 is unkown at this point).

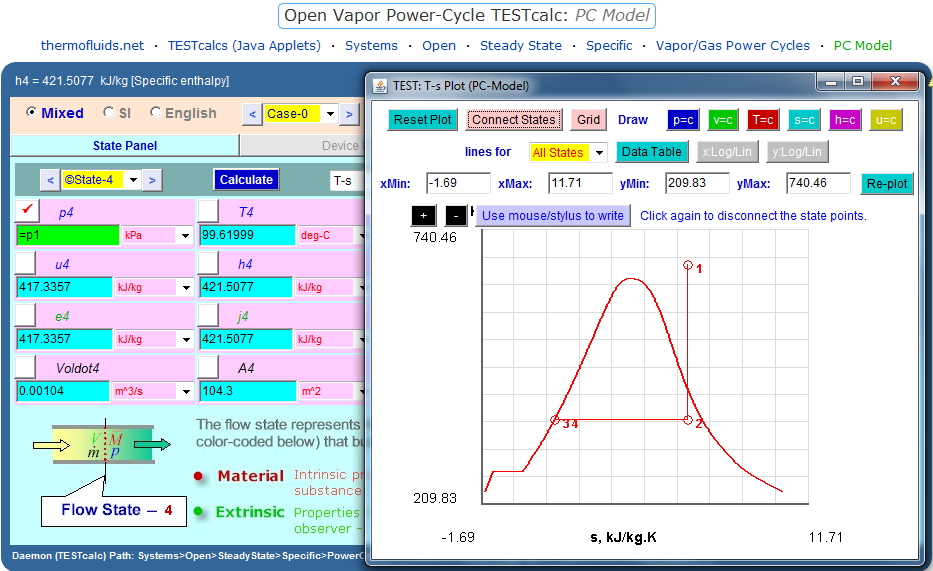

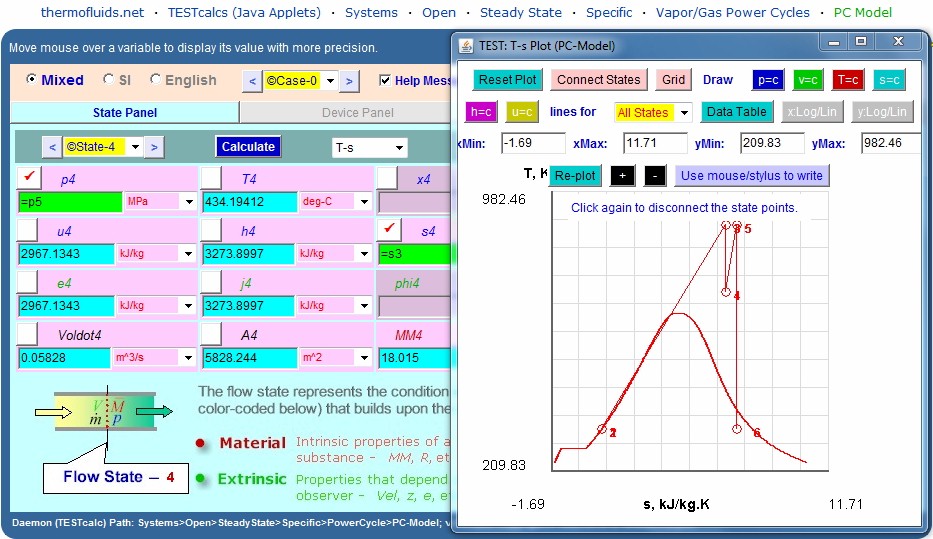

State-4: Enter p4 ('=p1'), s4 ('=s3') and Calculate (mdot4 is never used and so can be left unknown).

State-5: Enter p5 ('=p4'), h5 ('=h3+(h4-h3)*0.88'), mdot5 ('=mdot1-mdot3'), and Calculate (mdot5 is unkown at this point).

State-6: Enter p6 ('=p4'), x6 ('=0', saturated liquid), mdot6 ('=mdot1-mdot3'), and Calculate (mdot6 is unkown at this point).

State-7: Enter p7 ('=p2'), s7 ('=s6') and Calculate (mdot7 is never used and so can be left unknown).

State-8: Enter p8 ('=p2'), h5 ('=h6-(h6-h7)/0.8'), mdot8 ('=mdot1-mdot3'), and Calculate (mdot8 is unkown at this point).

State-9: Enter p9 ('=p2'), x9 ('=0', saturated liquid), mdot9 ('=mdot1'), and Calculate.

State-10: Enter p10 ('=p1'), s10 ('=s9') and Calculate (mdot10 is never used and so can be left unknown).

State-11: Enter p11 ('=p1'), h11 ('=h9-(h9-h10)/0.8'), mdot11 ('=mdot1'), and Calculate.

Having evaluated the principle states as best as possible, it is time for setting up the devies. Switch to the device panel and analyze each device as follows.

Device-A (Turbine): Load state-1 as the i1-state, and state-3 and 5 as the e1 and e2 states respectively. Enter Qdot=0, and Calculate. Wdot_ext cannot be calculated at this time as mdot3 is still an unknown.

Device-B (Condenser): Load state-5 as the i1-state and state-6 as the e1-state, enter Wdot_ext=0, and Calculate. Qdot is unknown at this point.

Device-C (Pump): Load state-6 as the i1-state and state-9 as the e1-state, enter Qdot=0, and Calculate. Wdot_ext is is unknown at this point.

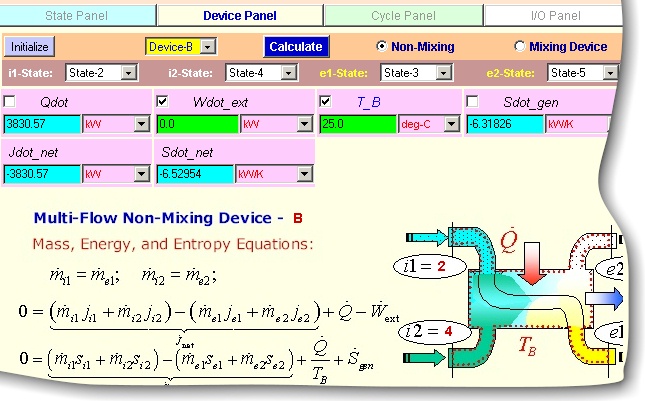

Device-D (Heater): Load state-3 and 8 as the i1 and i2 states and state-9 as the e1-state. Enter Qdot=0 and Wdot_ext=0, and Calculate. The energy equation produces mdot3 and posts it back to state-3 as shown below. The fraction of steam that is extracted at state-3 is, therefore, 0.1924.

At this point we can do a Super-Cal to update all calculations. However, a few more devices remain to be analyzed.

Device-E (Pump-II): Load state-9 as the i1-state and state-11 as the e1-state, enter Qdot=0, and Calculate. Wdot_ext is calculated as -10.11 kW.

Device-F (Boiler): Load state-11 as the i1-state and state-1 as the e1-state. Enter Wdot_ext=0, and Calculate Qdot=2814 kW.

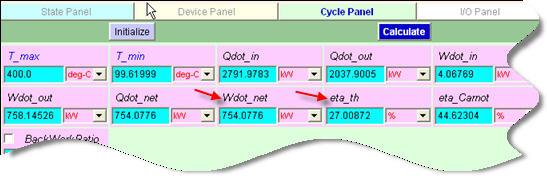

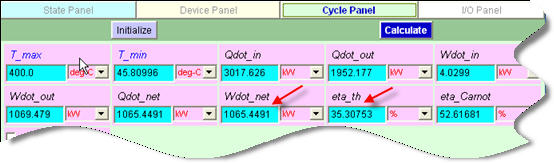

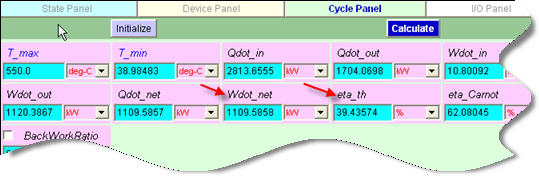

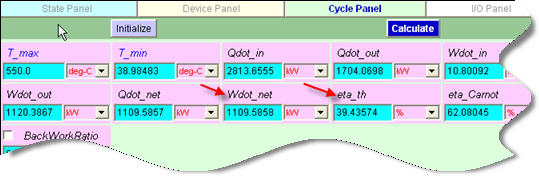

Super-Cal one more time to update the cycle panel. The thermal efficiency and net output are calculated as 39.44% and 1109.6 kW respectively.

For the what-if scenario, change p2 to 500 kPa, press the Enter key, and Super-Cal. The new answers are found to be mdot3=0.1764 kg/s, eta_th=39.35%, and Wdot_net= 1129.6 kW.

The TEST-Codes for the problem are reproduced below, which can be used to instanly regeneratre the solution (simply paste the TEST-code into the I/O panel, click the Load button and then Super-Cal). |